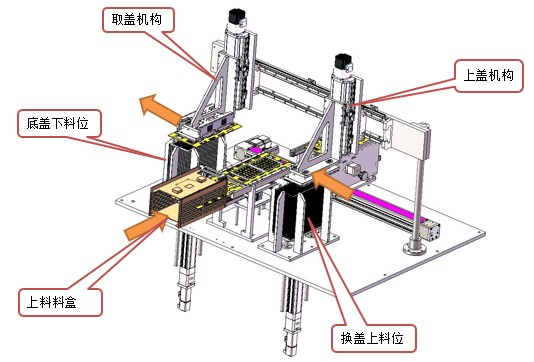

Boat cover feeder

The jig plate with bottom cover, after being pushed out of the material box, to the position of changing the cover, remove the original cover plate, put it on a new cover plate, and transport to the next station after completion

1. After the product is sent to the lid removal position, position it and clamp it, and the bottom is lifted up, and the bottom of the production opening is vacuum sucked to prevent the product from being carried up when the lid is removed

2. When the positioning preparation is completed, the cover removal mechanism removes the cover by clamping and adding a suction cup

3. When the original cover is removed, the cover mechanism will additionally suck the new cover to cover the product

4. After the above actions are completed, the product is sent to the next process

5. Repeat the above actions to complete the cap changing and feeding action.

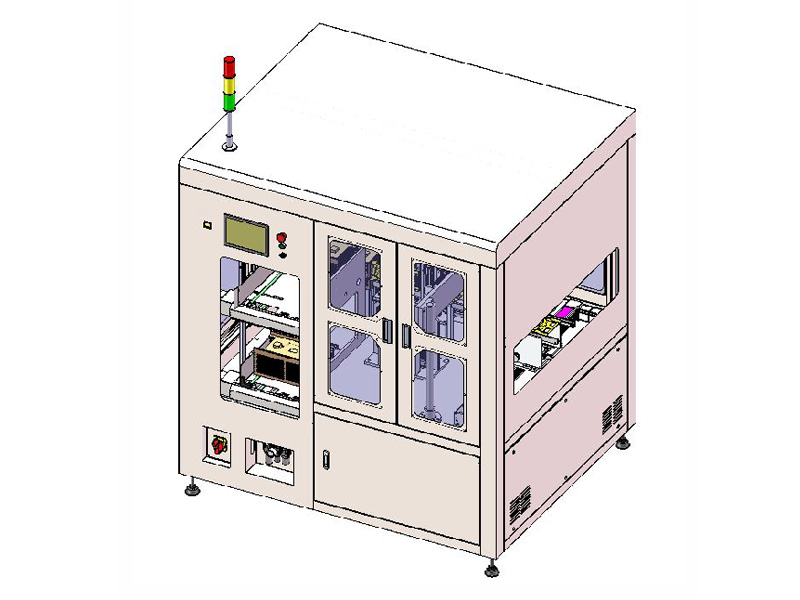

- Technical Data

- Overview

| Dimensions | L1310*W1310*H1750 |

| Capacity | Put a cover in 10 seconds |

| The loading part can be put in the turnover box | 9 in total; 4 full bins, 4 empty bins, 1 working bin |

| Can put the cover | The height of stack cover is 200mm, about 200 cover |

| Power supply | AC220V 50HZ |

| Air source | 0.2~0.6MPa |