3D SPI

3D Inline Solder Paste Inspection system

PEMTRON's 3D Inline Solder Paste Inspection System using Moiré pattern combines 2D color images with 3D measurement data to provide more accurate and realistic 3D inspection image unlike the conventional method that displayed solder paste through a color map only.

● Industry-leading precision and reliability of inspection

- Eliminate shadow using Multi Projection

● Real Color Full 3D Imaging Technique

● Glue inspection greater than 2mm

● Perform 2D & 3D algorithms simultaneously

● 64 bit Windows 10 Operating System

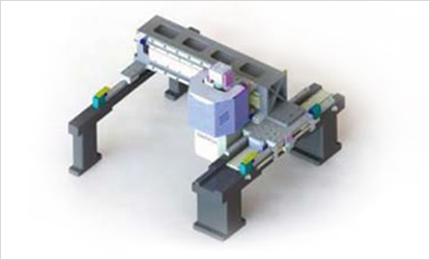

● Linear Motor Gantry Type Drive

- High-speed precision control improves repeatability

- Reduction of noise/vibrationd

- Technical Data

- Overview

THE MOST STABLE QUALITY SOLUTION

PEMTRON SPI uses superior optical technology compared to other SPIs to validate high precision and repeatability.

Various internally developed process control software identifies and statistically analyzes process problems.

It is a very effective tool for optimizing processes and improving production efficiency.

HIGH-SPEED, HIGH-PRECISION INSPECTION

Pemtron’s TROI SPI uses precise lenses and high-resolution cameras to examine for poor lead application without any problems and does it with precision and speed.

Based on high precision and repeatability, it is possible to respond to various conditions and perform stable inspections.

ENHANCED SPC SYSTEM

SPC data can be saved in a variety of file formats, such as HTML, Excel, and Image.

In addition, enhanced SPC server capabilities allow you to control multiple lanes of data together or individually.

Various information through Data Driven has been provided for systems that are reliable and improve production efficiency by providing integration and analysis.

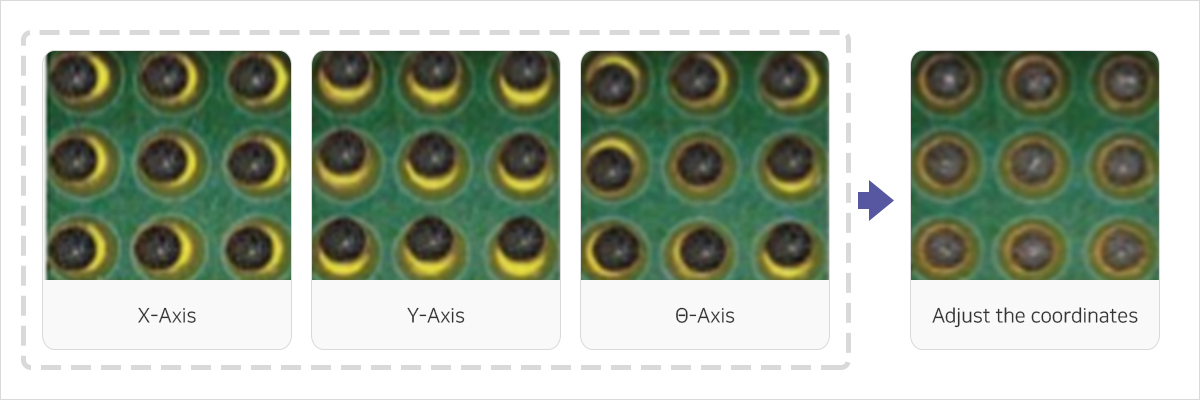

CLOSED LOOP

Real-time data communication with the screen printer and the mounter helps to solve fundamental problems and optimize the process by exchanging information such as the location of the pad and solder paste.

- Inspection Result Information Auto Sync.