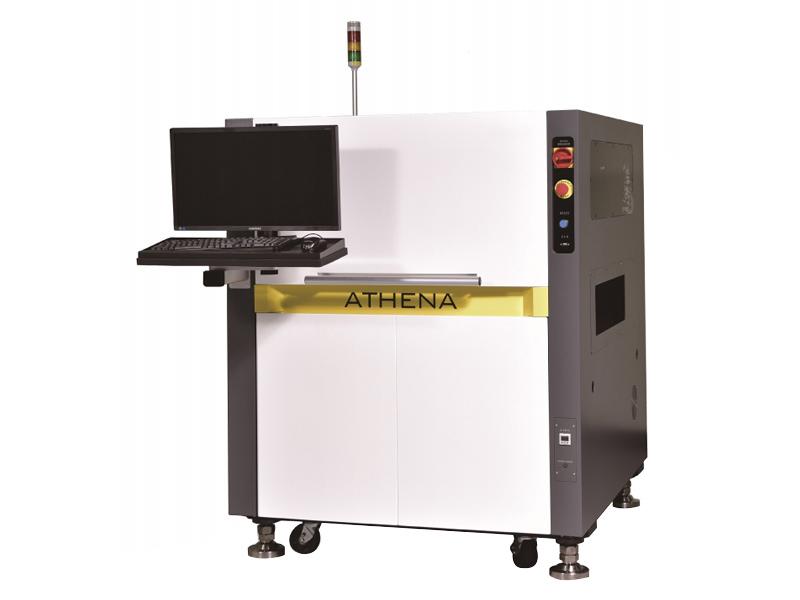

3D AOI

3D Automated Optical Inspection System

● Advanced 3D technology

● Stable and Accurate 3D realization by installing additional projectors

- 3D Formation of Chip among Dense Components and Narrow Parts

- 3D image Formation identical to a Real Image

● Improved Repeatability

- Accurate 3D inspection makes repeatability more reliable

● Simultaneous Inspection Algorithm (2D and 3D)

● Tele-centric Lens Offers Higher Accuracy & Detection

● High-Speed CPU & Image Process

● User-Friendly GUI

● Built in Library Management System

● Offline Real-Time Debug Station

● 4-Way side cameras (Optional)

- Technical Data

- Overview

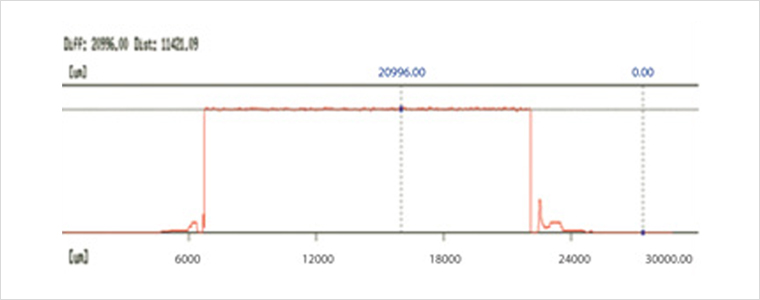

3D MEASUREMENTS FREE FROM SHADOWS AND REFLECTIONS

The EAGLE 3D 8800 AOI uses 8-way projection for 3D measurements on all models to minimize errors due to shadow effects, and performs 100% 2D & 3D concurrently in all FOV areas.

This significantly reduces the false call while providing near-perfect detection.

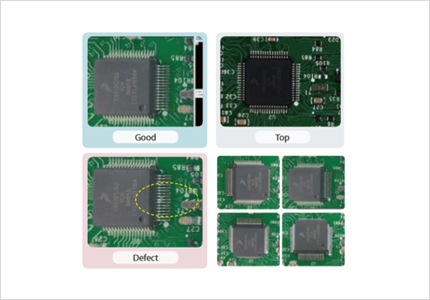

ACCURATE AND CONVENIENT INSPECTION USING SIDE CAMERA

Four high-definition cameras on the side and a dedicated algorithm optimized for both use and side inspection is available for real-time inspection.

4-Way Side Camera (Optional)

Internal bridge detection not found in Top Camera

Connector internal detectable

Convenient Teaching Using Existing Algorithm

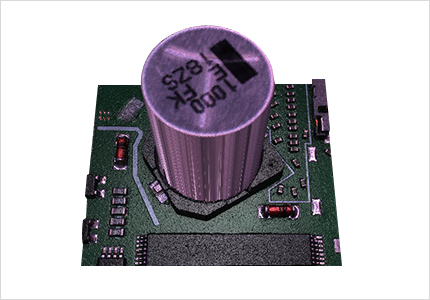

27mm high part 3D measurement/inspection

EAGLE 3D AOI offers the option of inspecting up to 30mm in height components with a unique PEMTRON technology.