One point two (two in one)

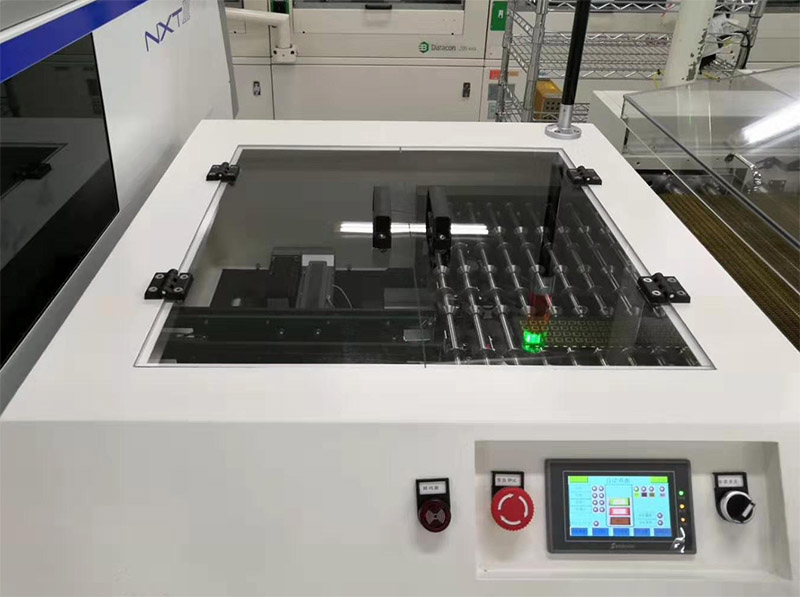

One-in-two (two-in-one) equipment is mainly used between the AOI inspection machine and the placement machine, and the automatic plywood machine (board splitting machine) is mainly used before or after the reflow furnace. The main difference between the two devices is the type of connected devices. The boarding machine (board splitting machine) can realize the five-track feeding of the reflow furnace, and the accuracy of the feeding position is low. The one-in-two (two-in-one) equipment has high requirements for the accuracy of the feeding position and can accurately convey the material to the next machine.

- Technical Data

- Overview

One-in-two (two-in-one) equipment is mainly used between the AOI inspection machine and the placement machine, and the automatic plywood machine (board splitting machine) is mainly used before or after the reflow furnace. The main difference between the two devices is the type of connected devices. The boarding machine (board splitting machine) can realize the five-track feeding of the reflow furnace, and the accuracy of the feeding position is low. The one-in-two (two-in-one) equipment has high requirements for the accuracy of the feeding position and can accurately convey the material to the next machine.

One-in-two (two-in-one) equipment is mainly used between the AOI inspection machine and the placement machine, perfectly connecting the AOI's single-track output and the placement machine's dual-regulation feeding, realizing automatic feeding to the subsequent equipment, improving the equipment (Two-in-one is to convert the dual track of the placement machine into a single track of AOI).