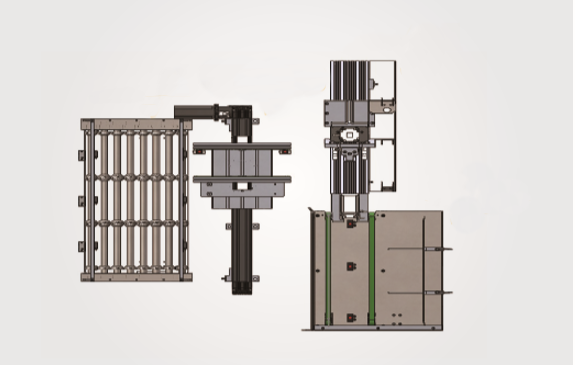

Blanking machine

1. Fully automatic loading machine for substrate packaging on SMT production line

2. Electric cylinder imported from Japan to ensure accurate mechanical control

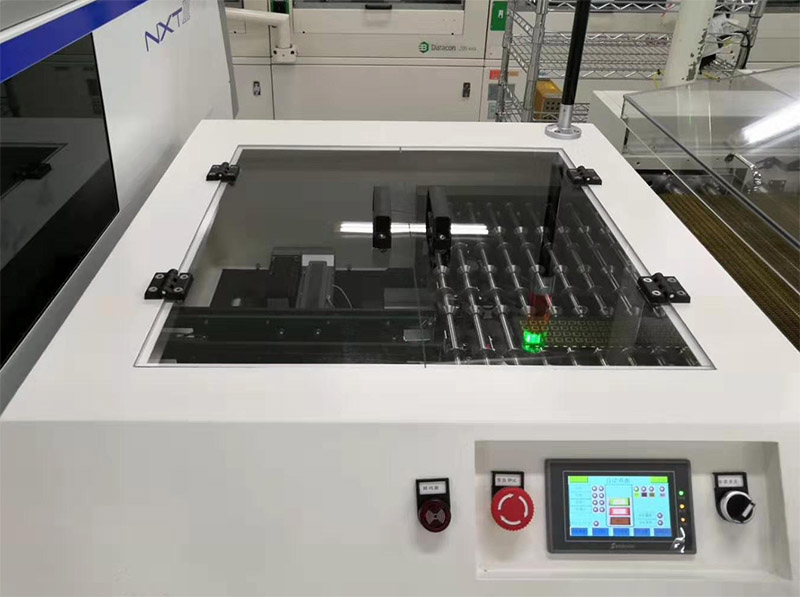

3. PLC control, color man-machine interface

4. The duty platform automatically rises and falls, and the speed is adjustable.

5. Sound and light prompt alarm system, text prompt for abnormal information, easy operation and maintenance

6. Standard SMEMA signal communication method

7. The equipment is pushed and transported with protective sensors to prevent the product from being broken

8. The width of the equipment track can be adjusted, which is suitable for products of various specifications

9. The equipment has power-off protection and protects the product from damage

- Technical Data

- Overview

|

Project |

Sort |

Detail |

|---|---|---|

|

Equipment capacity |

Processing capacity |

10 seconds/piece (according to the needs of downstream equipment, can be customized) |

|

Corresponding type |

Multiple |

|

|

Frame size |

25-110 (According to customer needs) |

|

|

Other composition |

Dimensions |

1540(W)×960(D)×1800(H) |

|

Weight |

600kg |

|

|

Power supply |

AC220V single phase |

|

|

Air supply |

6Mpa |

|

|

Device control |

PLC control |

|

|

Surface resistance value of ESD machine |

≤10Ω |

|

|

External machine |

Indicator light, operation SW, touch screen |