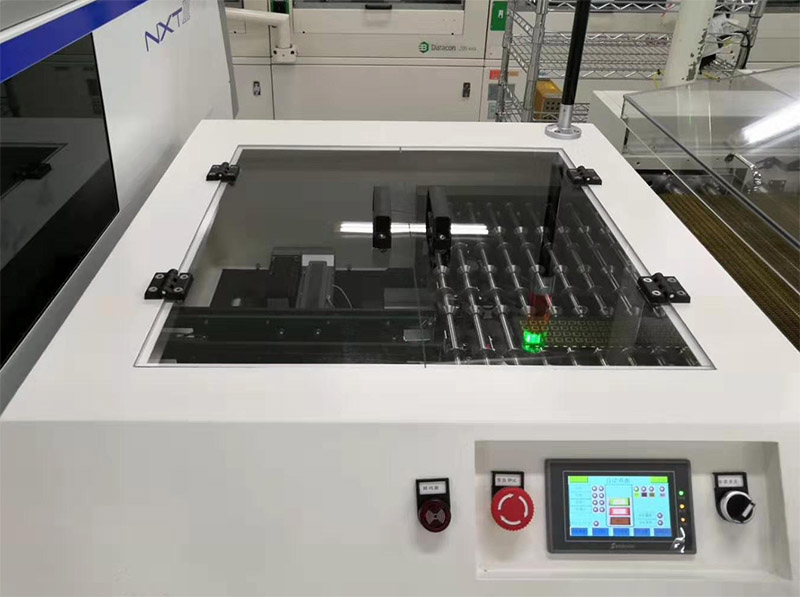

Splitting machine (plying machine)

Fully automatic plywood machine (splitting machine) is mainly used in front of or after the reflow furnace to realize automatic feeding to the subsequent equipment. It can be adjusted according to the width of the front machine to achieve five-track simultaneous work (special models can be customized). The multi-track transmission of the front machine is perfectly connected, and it is transformed into a single-track conveying to the rear machine (the splitting machine is to convert a single track into a multi-track to realize the connection between different production equipment).

Features:

1. PLC control, color man-machine interface

2. Standard SMEMA signal communication method

3. The equipment is pushed and transported with protective sensors to prevent product damage

4. The width of the equipment track is adjustable, suitable for products of various specifications

5. The equipment has power-off protection and protects the product from damage

- Technical Data

- Overview

|

Project |

Sort |

Detail |

|---|---|---|

|

Equipment capacity |

Processing capacity |

10 seconds/piece (according to the needs of downstream equipment, can be customized) |

|

Corresponding type |

Multiple |

|

|

Frame size |

25-110 (According to customer needs) |

|

|

Other composition |

Dimensions |

900(W)×960(D)×1042(H) |

|

Weight |

600kg |

|

|

Power supply |

AC220V single phase |

|

|

Air supply |

6Mpa |

|

|

Device control |

PLC control |

|

|

Surface resistance value of ESD machine |

≤10Ω |

|

|

External machine |

Indicator light, operation SW, touch screen |

Fully automatic plywood machine (splitting machine) is mainly used in front of or after the reflow furnace to realize automatic feeding to the subsequent equipment. It can be adjusted according to the width of the front machine to achieve five-track simultaneous work (special models can be customized). The multi-track transmission of the front machine is perfectly connected, and it is transformed into a single-track conveying to the rear machine (the splitting machine is to convert a single track into a multi-track to realize the connection between different production equipment).

Features:

1. PLC control, color man-machine interface

2. Standard SMEMA signal communication method

3. The equipment is pushed and transported with protective sensors to prevent product damage

4. The width of the equipment track is adjustable, suitable for products of various specifications

5. The equipment has power-off protection and protects the product from damage