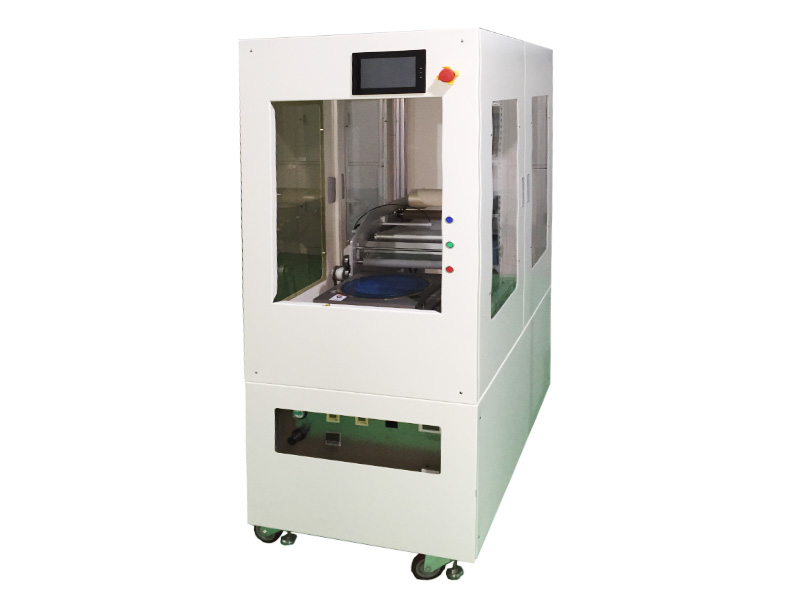

Stencil cleaning machine

Features of SME-800 Stencil cleaning machine

1. Comprehensive cleaning machine, which can clean SMT steel mesh, copper mesh, resin mesh, SMT scraper, misprinted PCB, PCBA, etc.

2. The whole body is made of stainless steel, anti-acid and alkali corrosion, strong and durable

3. The industry's better design of motion mechanism-the steel mesh moves back and forth, the spray bar and the air knife are fixed, the machine runs more stable

4. The water-based steel mesh cleaning fluid is filtered in real time to extend the saturation time of the pollutant load, which is suitable for cleaning precision steel mesh

- Technical Data

- Overview

|

序号 |

名称 |

规格 |

备注 |

|---|---|---|---|

|

1 |

适用网版尺寸 |

L750*W750*H40(mm) |

最大 |

|

2 |

液箱/水箱容量 |

60L/60L |

|

|

3 |

清洗时间 |

3~5min |

锡膏钢网 |

|

4 |

漂洗时间 |

1~2min |

锡膏钢网 |

|

5 |

干燥时间 |

3~6min |

锡膏钢网 |

|

6 |

清洗,漂洗压力 |

4~5kg/cm2 |

|

|

7 |

清洗液 |

水基清洗液 |

|

|

8 |

漂洗液 |

DI水(DM水) |

|

|

9 |

干燥方式 |

高压热风 |

|

|

10 |

液体加热温度 |

0~60℃ |

|

|

11 |

烘干温度 |

0~90℃ |

|

|

12 |

清洗加热功率 |

9KW |

|

|

13 |

漂洗加热功率 |

9KW |

|

|

14 |

干燥加热功率 |

6KW |

|

|

15 |

清洗/漂洗过滤 |

1um/1um |

实时循环过滤 |

|

16 |

电源/气源 |

AC380V,50/60HZ,28KW /0.5~0.7Mpa,200~400L/Min |

|

|

17 |

重量 |

720KG |

|

|

18 |

机器尺寸 |

L1300*W1400*H1970(mm) |

|

Features of SME-800 Stencil cleaning machine

1. Comprehensive cleaning machine, which can clean SMT steel mesh, copper mesh, resin mesh, SMT scraper, misprinted PCB, PCBA, etc.

2. The whole body is made of stainless steel, anti-acid and alkali corrosion, strong and durable

3. The industry's better design of motion mechanism-the steel mesh moves back and forth, the spray bar and the air knife are fixed, the machine runs more stable

4. The water-based steel mesh cleaning fluid is filtered in real time to extend the saturation time of the pollutant load, which is suitable for cleaning precision steel mesh

5. Large flow double 4 air knife system, hot air drying quickly

6. One-button operation, cleaning, rinsing and drying are automatically completed in one time according to the set program

7. The cleaning room is equipped with a visual window, and the cleaning process is clear at a glance

8. At the end of cleaning, compressed air is used to recover the residual chemical liquid in the pipeline and pump, effectively saving cleaning solution

9. The panel is equipped with a pressure gauge, which displays the pressure of cleaning, rinsing, and cleaning filter barrels.

10. Color touch screen, PCL control, can set cleaning fluid temperature, cleaning time, rinsing fluid temperature, rinsing time, rinsing times, drying time, drying temperature and other parameters

11. Equipped with automatic liquid filling and draining functions

12. Mitsubishi, Schneider, SMC and other high-quality electrical components are durable, safe and reliable.