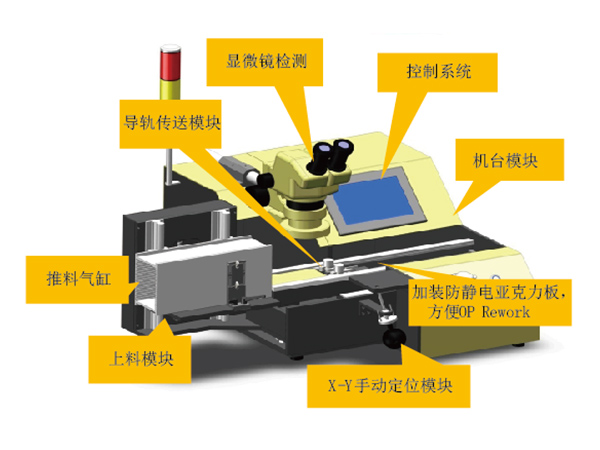

Sanko Machine ALPARK-C

ALPARK-C semi-automatic three-time light inspection machine has six modules: feeding module, rail conveying module, microscope inspection, X-Y manual positioning module, machine module, and control system. The operator inspects each IC on the strip through a high-power microscope and judges whether it is qualified.

Features

1. Using a high-power microscope to detect strips, the operation is simple and reliable, and the cost is low.

2. The width of the strip guide is electrically adjusted, and once the position parameter is adjusted, it can be recorded for the next call. Manual adjustment is avoided, and the efficiency of refueling and debugging is greatly improved.

3. The gripper of the material strip has a safety mechanism to ensure that the material strip is not damaged during movement.

4. The design of double electromagnetic claws makes the strip drag more smoothly.

5. The man-machine interface adopts touch screen.

6. Reduce artificial handing problems

7. Equipment can be customized according to different requirements of customers

- Technical Data

- Overview

| Positioning accuracy | 0.05mm |

| Adapted strip width | 40-80mm |

| Dimensions |

804×634×331mm(L×W×H)

|

| Weight | 40KG |

| Operating Voltage | 220VAC |

| Gas source | 5Kg/cm2 |

Features

1. Using a high-power microscope to detect strips, the operation is simple and reliable, and the cost is low.

2. The width of the strip guide is electrically adjusted, and once the position parameter is adjusted, it can be recorded for the next call. Manual adjustment is avoided, and the efficiency of refueling and debugging is greatly improved.

3. The gripper of the material strip has a safety mechanism to ensure that the material strip is not damaged during movement.

4. The design of double electromagnetic claws makes the strip drag more smoothly.

5. The man-machine interface adopts touch screen.

6. Reduce artificial handing problems

7. Equipment can be customized according to different requirements of customers

Functional Overview

The electromagnetic claw automatically completes the extraction and return of the strip.

The electromagnetic claw drags the strip to step.

The material box lifting device enables the electromagnetic claw to select different material strips in the material box.

The width of the strip guide is electrically adjustable.

The double electromagnetic claw design makes the gripping movement of the strip more balanced and smooth.

The electromagnetic claws are specifically designed for safety to ensure that the strip is not damaged during the movement.

It can memorize the data of different materials and automatically adjust the equipment in place according to the selection.

According to different products, the phase program can be stored in the machine.